Bơm xả lũ KSB AMACAN P

TRẠNG THÁI: Hàng mới 100%

Giá bán: Vui lòng liên hệ

Danh mục: Bơm KSB (Đức)

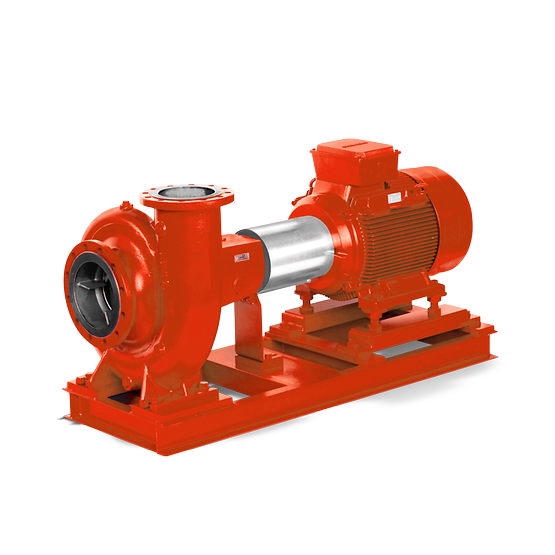

Design

Wet-installed, submersible motor pump with axial propeller in ECB design for installation in discharge tubes, single-stage, single-entry, explosion protection to ATEX II G2 T3.

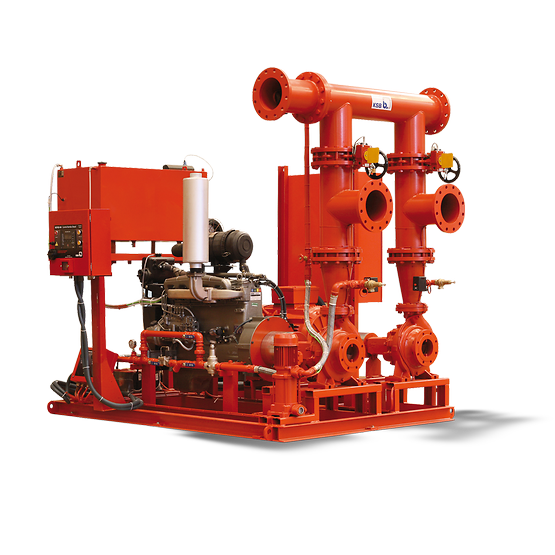

Applications

Irrigation and drainage pumping stations, stormwater pumping stations, handling of raw and clean water in water and effluent treatment plants, of cooling water in power stations and industrial plants, industrial water supply systems, water pollution and flood control systems, aquaculture.

| Type of impeller | Axial; Open;Propeller |

| Type of installation | Close- coupled |

| Maximum drive rating | 700 kW |

| Impeller material (EN standard) | 1. 4517 |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 1. 750 1/min |

| Maximum flow rate | 25. 200 m³/h |

| Casing material (EN standard) | JL 1030 |

| No. of impeller entries | Single entry |

| Casing material | Cast iron |

| Minimum flow rate | 360 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| eClass assignment | 36410101; 36410106 |

| Pump set location | 00 |

| Explosion protection | ATEX II 2G T3 |

| Max. permissible fluid temperature | 40 002 |

| Free passage | 255 mm |

| Main applications | Energy; Mining / Dredges;Water;Waste water / sewage |

| Type of installation | Stationary |

| Type of casing | Tubular casing |

| Type of lubrication | Grease lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | 1. 4057.05;1.4021.05 |

| Type of coupling | None |

| Shaft seal type | Mechanical seal |

| Drive | Electric motor |

| Maximum head | 12, 00 m |

| Minimum head | 0, 80 m |

| Nozzle position | In- line |

| Casing partition | Radially split |

| Connection to power supply | 380 V, 400 V, 690 V, 3~ |

Gọi điện

Gọi điện

Tin nhắn

Tin nhắn