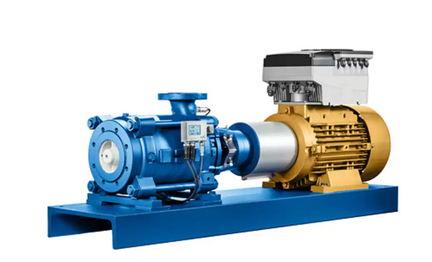

Bơm chìm

TRẠNG THÁI: Hàng mới 100%

Giá bán: Vui lòng liên hệ

Danh mục: Bơm KSB (Đức)

Submersible motor pumps DN 40 to DN 350

Cast iron and various materials for industrial effluents

Motor ratings up to 175 kW.

50 Hz

standard range

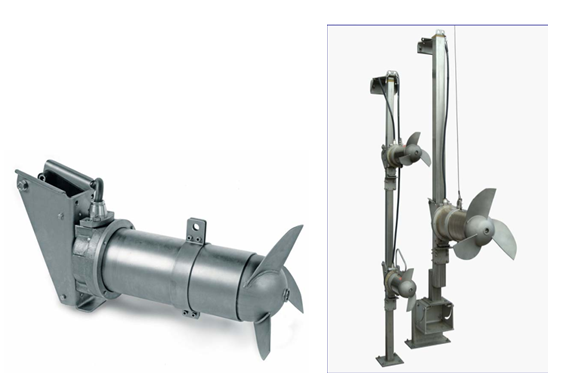

Stationary installation

Transportable installation

Designs incorporating features

which are out side the

documented standards must

comply with the appropriate

conditions of application which

will be provided upon request.

1.0 Applications

KRT submersible motor pumps are used for pumping all types

of sewage and effluent in water treatment and industry,

especially untreated sewage with long fibrous and solid

substances, liquids containing air and gas as well as raw,

activated and digested sludge.

2.0 Operating data

| Capacity | Q up to 3200m3/h, 900 l/s |

| Head Motor power Temperature of pumped liquid Enclosure type |

H up to 95 m P2 from 11.0 kW to 175 kW T up to 400C |

| IP 68 as per IS/IEC 60034-5 |

4.0 Drive

Three–phase asynchronous motor;

415 V + 10% -15%

50Hz –5%

5.0 Material

Standard version of cast iron with stainless steel impeller

G = All main parts in Cast iron - (cast iron casing and Cast

iron impeller).

G1 = all main parts in Cast Iron only and impeller in

Satinless steel - (NiCI casing and CF8M impeller).

6.0 Shaft sealing (Bellow Type)

Two mechanical seals being independent of the direction of

rotation, lubricated with oil and in tandem arrangement.

For jacket cooling, cooled by internal cooling fluid

7.0 Bearings

Grease lubricated ball and roller bearings for drive end and non

drive end.

8.0 Standards

• Performance as per DIN EN ISO 9906, Gr. 3B.

For motors upto 10 kW - Refer Section 4.4.2

• Balancing of rotors as per ISO 1940 Gr. 6.3

• Cables as per IS 9968-1

3.0 Designation

Example

KRT K 150-315 / 11 4 U G1 - P

Pump type

Impeller type ( E, K, F)

Hydraulics dimension

Motor size

No. of Poles

Motor Version (U/UN)

Material version / variant (G, G1)

Installation Type

(S = stationary without cooling jacket, P = transportable

without cooling jacket, K = stationary with cooling jacket.)

Gọi điện

Gọi điện

Tin nhắn

Tin nhắn